STS offers DRC and DFM Service for PCB

Printed Circuit Board DRC/DFM Service for Board and Assembly

The amount of connections on a PCB increases steadily, due to new components with more and more functions. The count of layers and nets is directly influenced by this trend. Of course, that also results in more and more rules when performing checks for quality reliable products. We support Electronic Developers in one of their major functions, namely improving the functionality of the device by giving them time. However, it is necessary to take care of the fabrication of the whole product.

The challenge is to combine these three things: accelerating the time-to-market, providing higher quality for customers and reducing costs at the same time. Our mission is to provide tools to facilitate the analysis of bare boards and to provide full assembly support. Performing analyses usually takes many hours for the developer team. With our DRC/DFM and Conversion Service, we can give back the full amount of time to developers.

What are the advantages of DRC/DFM as a Service?

- Save time for your team

- The applied rules rely on manufacturing experience

- Mapping layers are already combined and will be checked combined to find E-CAD export issues

- The DRC is done on the output data, not on internal net information of the used CAD System

Get one Design Review for free. Sign up now.

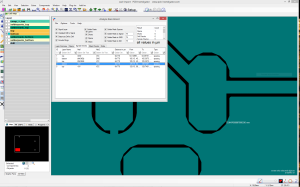

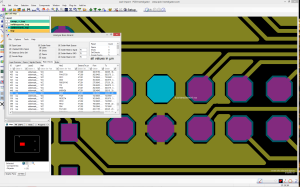

Get a full analysis of all layers

- Copper distance

- Stubs (Lines and Arcs end in empty space)

- Mask to Drill distances

- Mask to Signal distances

- Mask to SMD distances

- Opens

- Shorts

Design Spin Change Report

- differences of all PCB layers

- differences of component properties. Reference, part name, geometry….

- differences of net connections, net list tracking

ODB++ to Gerber Compare Report

- differences of all PCB layers

ODB++ to IDF 2.0/3.0 Compare Report

- differences of component properties. Reference, part name, geometry….

Design Overview Report

- Component and Layer Attributes

- Layer Matrix

- PCB and Panel Bounds

- PCB Attributes

- BOM Information

- Bare Board Analysis Issue Report

Test Point Report

- Net list with testpoint count and position

Specials

- Component analysis for SMD Assembly

- Tombstone analysis for SMD Assembly

- Hazard analysis for Net Tracking

Request a quote

Please contact us to receive a non-binding offer

for the desired product.